Extrusion Blow Molding Machine for Small Bottles or Containers PT-2LII

- Suitable Bottle Size: 20–2000ml

- Suitable Bottle Neck: 18–38mm

- Production Capacity: 300-1,000BPH

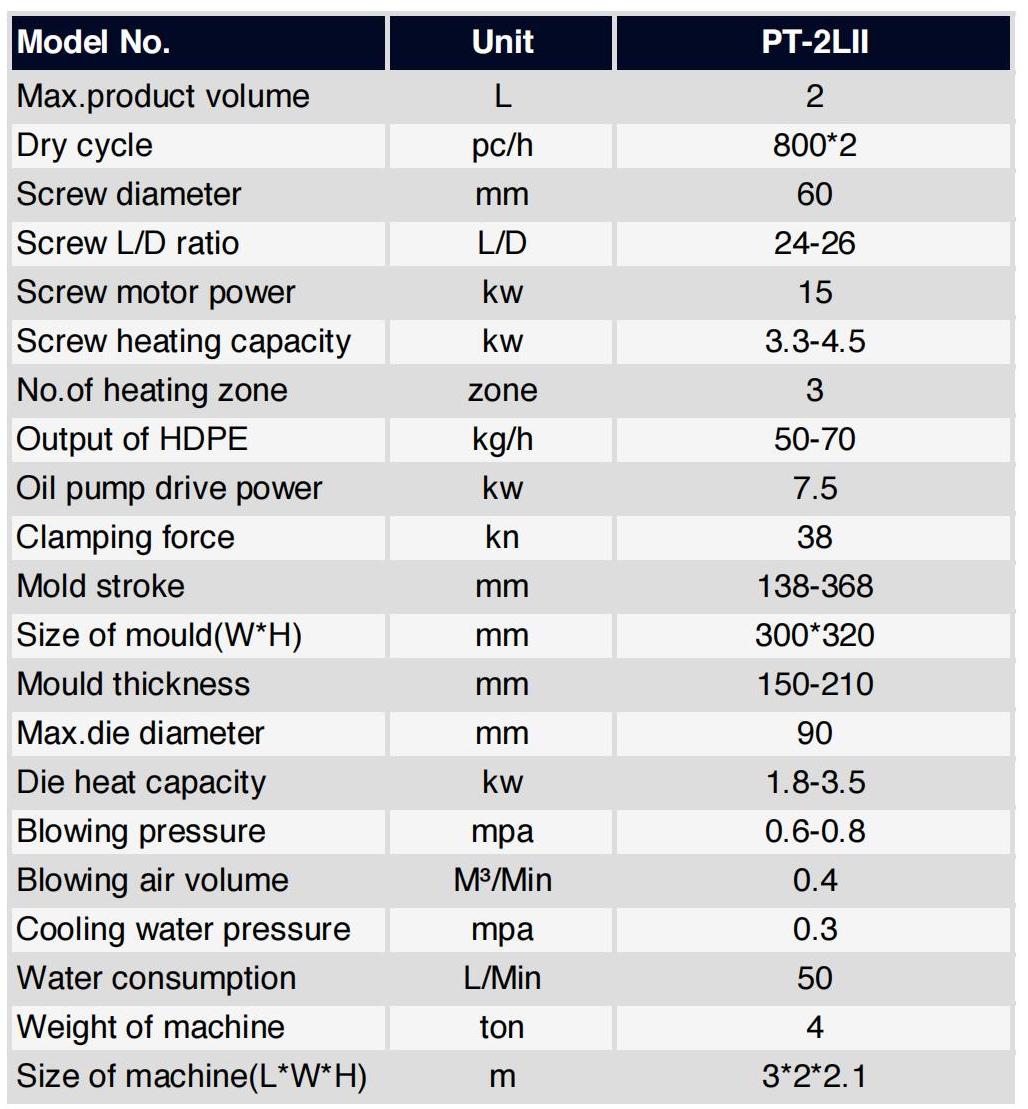

- Technical Parameter

- Description

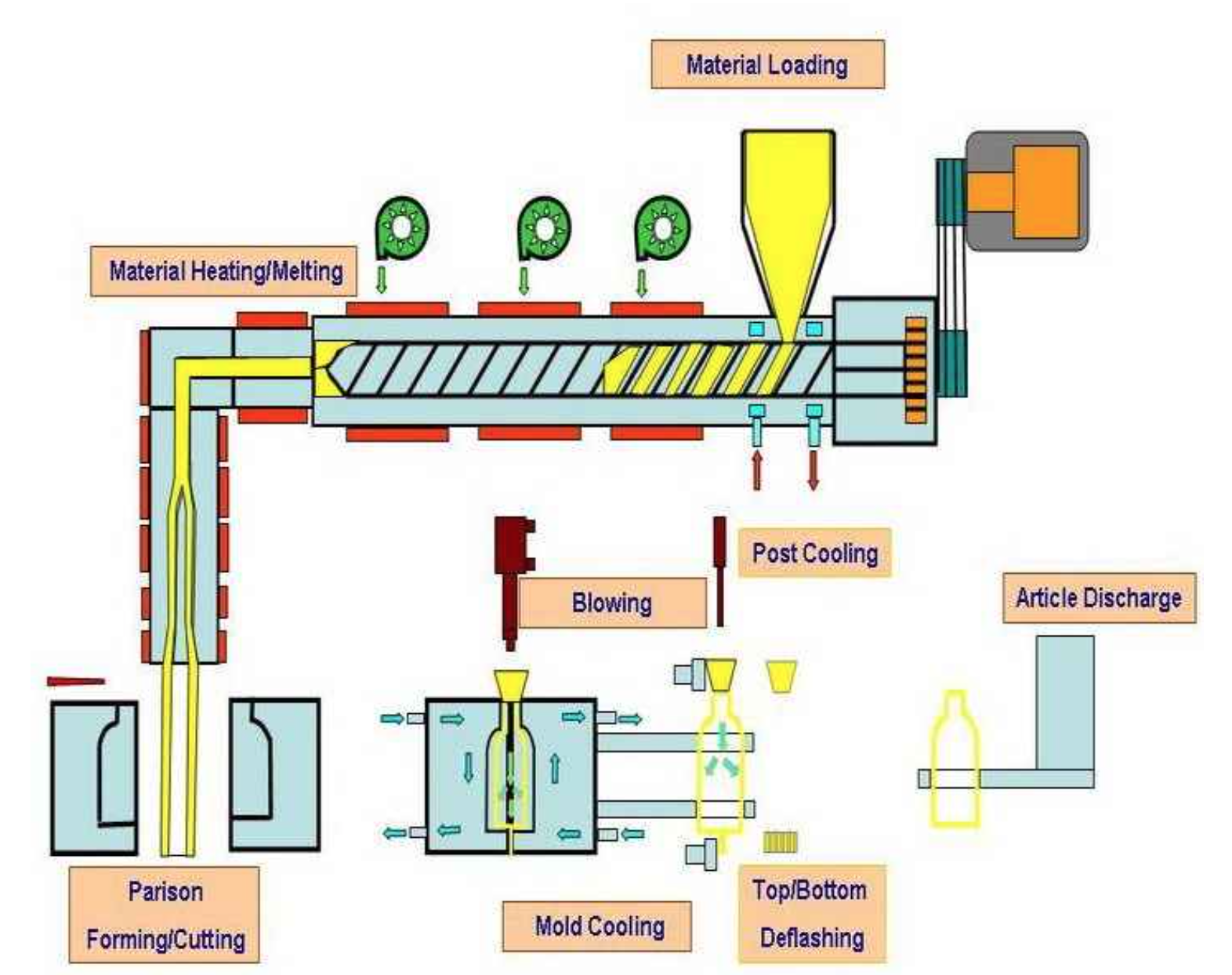

- How Do Extrusion Blow Molding Machine Work?

- Inquiry

HDPE/PP Extrusion Blowing Machine General Introduction

1. Extrusion blow molding machine is a single station machine, and suitable for producing high quality container with medium output with from one to six fold die head, for use in the packaging of petroleum, cosmetics, chemicals, pharmaceuticals, food, toys and auto-parts.

2. The clamping system is a high-precision single-station linear guide, extrusion system using a hard gear reducer and inverter imported from Japan.

3. The die head system adopts central-incoming extrusion die made of special steel, imported hydraulic valve and seal parts with proportional control valve.

4. The control system consists of PLC and Human-machine interface imported from Japan, an automatic temperature control module and imported electrical part.

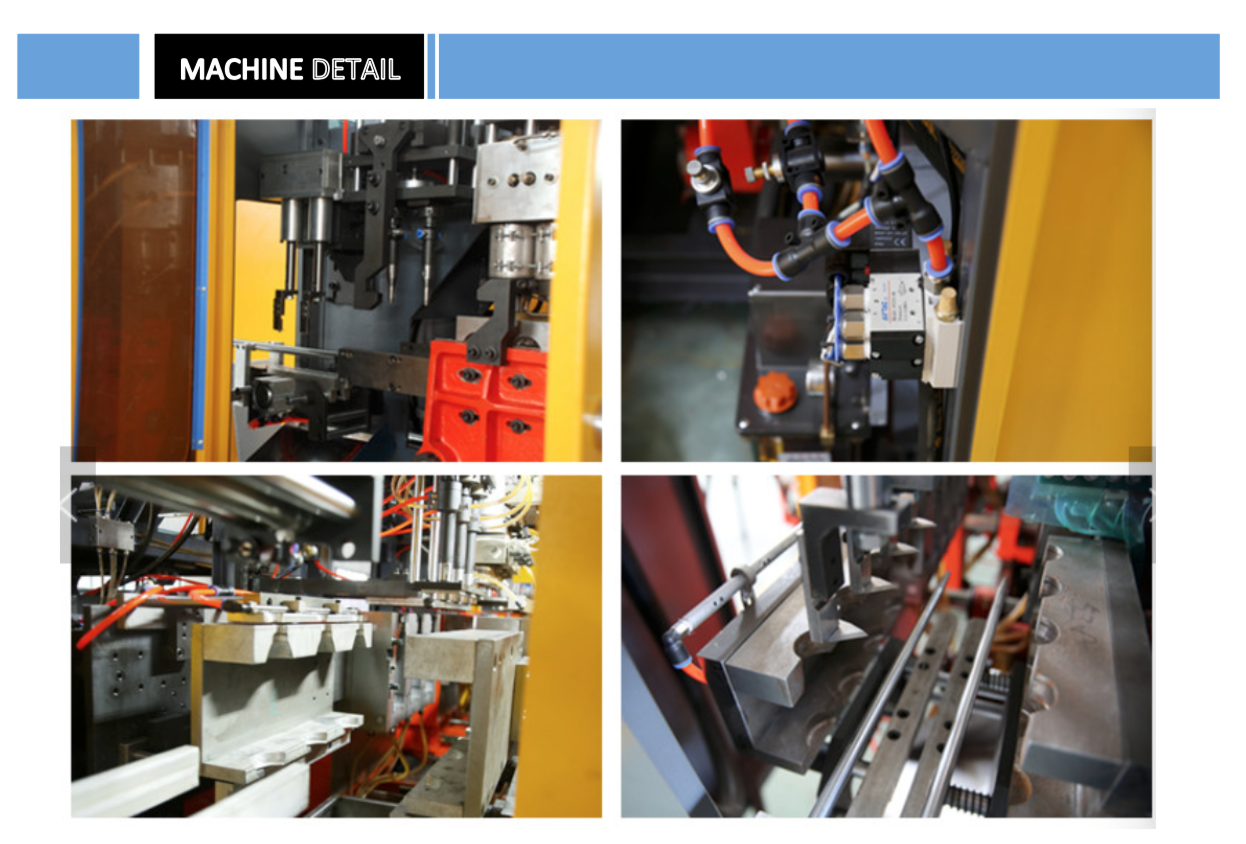

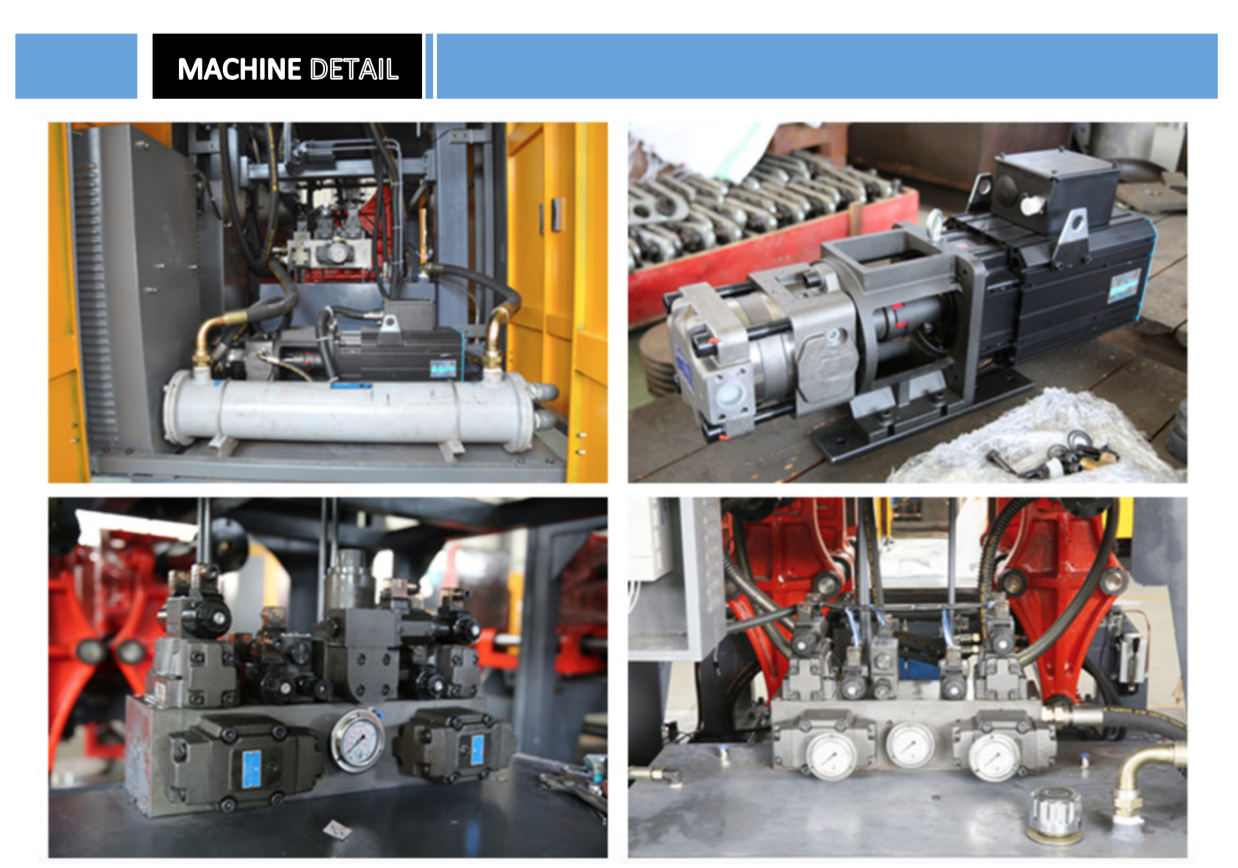

DHPE/PP Extrusion Blowing Machine Basic Components

1. Die: Vertical first-in first-out structure

2. Extruder unit: Imported automatic temperature control module, with the screw driven by converter electrical machine and hard gear surface reducer to achieve infinite speed variation.

3. Clamping unit: Hydraulic fixed bi-directional clamping system with good stability.

4. Hydraulic system: Imported hydraulic unit and proportional control.

5. Electrical system: Siemens PLC, world brand, electrical components

Extrusion Blow Molding Machine Detail