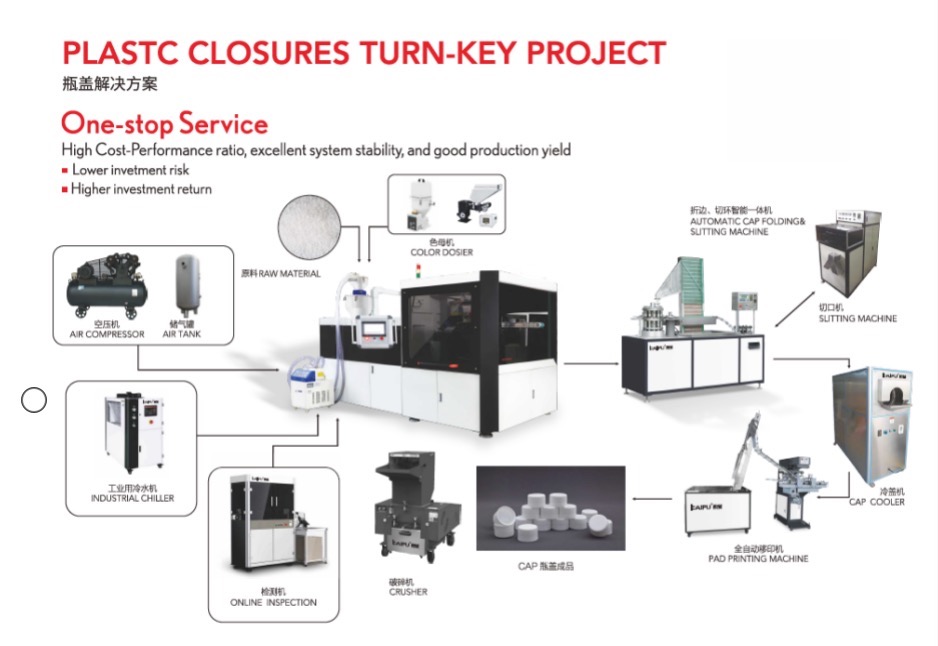

Cap Compression Molding Machine with 16 Cavity Cap Mold

PET-C16,C24 and C36 Cap compression molding machine is used to make soda cap and water cap by high temperature plasticizing.This machine is easy to operate, saving electricity, water and labor cost. Compared with the same energy consumption injection machine, the production can be growth to three or four times.Besides, there is no any wasted material. So it decreases the cost of cap making greatly.

- Description

- Inquiry

Cap Compression Molding Machine C16, C24 and C36 adopts continuous compression molding hydraulic press for plastic cap manufacturing via the extrusion of dry-blend granulated compounds (i.e. HDPE, PP), metering, pelletting and insertion in the cavities to mould it into the final shape. The capacity of the machine depends heavily on compound properties and the geometry of the manufactured caps.

Cap Compression Molding Machine Equipment Advantages.

1. Intelligent PLC controlling system

2. Human-machine interface, easy & stable operation

3. Machine adopts world-class industry design and processing crafts, exquisite electrical configuration and superb assembling technology

4. Easy computer operation realizes full-auto production from PP&PE resin to final caps.

5. Rotation compressing cap molding offers shorter recycling time, high yielding and fine final caps, caps with no injection point and easy for cap logo printing

6. Cap with high density, short change-over time for one color cap to another.

7. Low energy consumption,output triples compared with the traditional cap injection molding machine

8. Each cap mold is independently compressed, no runner scrap.

9. Easy and low cost mold maintenance

10.High efficiency, low price of our Cap Compression Molding Machine

Bottle Cap Making Machine Technical Information

| Model | PET-C16 | PET-C24 | PET-C36 |

Production Capacity | 19000PCS/H (2925mm) 17000PCS/H (3025mm) | 30000PCS/H (2925mm) 28000PCS/H (3025mm) | 52000PCS/H (2925mm) 46000PCS/H (3025mm) 25000PCS/H (1881 neck without folding) |

| Cap Diameter | 22-42mm | 22-42mm | 20-42mm |

| Cap Height | 15-25mm | 15-25mm | 15-25mm |

| Cap Material | PP/HDPE | PP/HDPE | PP/HDPE |

| Mold Cavity No. | 16 | 24 | 36 |

| Power | 380V/50Hz, Customized | 380V/50Hz, Customized | 380V/50Hz, Customized |

| Installation Power | Install power 50kw,actual power 28kw | Install power 67kw,actual power 38kw | Install power 96kw,actual power 57kw |

| Air Consumption | 0.6m3/Hr, 1.0Mpa | 0.6m3/Hr, 1.0Mpa | 1.0m3/Hr, 1.0Mpa |

| Machine Dimension | 3500*1700*2100mm | 3700*1770*2100mm | 5500*220*2100mm |

| Machine Weight | 4.0T | 5.5 T | 6 T |

Workshop View