Preform Feeding

√ Fully automatic preform feeding system.

√ Proper preform stabllization device.

Heating System

√ Modular oven.

√ Fan system is installed for oven heating.

√ Customized oven dimensions based on preform and max. bottle size.

√ Each lamp, each lamp gripper and each lamp rod is separately adjustable.

Preform Transfer

√ Servo-driven system:More precise and faster to transfer preform.

√ Special chain and chain connection guarantee chain system precision and extend chain system lifespan.

√ Self-lubricating bushing and sealed bearings.

√ Quick change of robot clips, mould & star-wheels(tool-less) for different bottle.

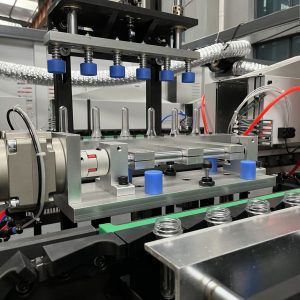

Clamping & Stretching System

√ Toggle structure & pressure increase dovice:Faster and strongor clamping to avoid disconnected parting surface.

√ Combination vaive: Faster air inlet and very quick air exhaust.

√ Individual cavity blowing individual cavity stretching individual cavity pre-blow are all separately adjustable.

√ Inbullt bigger air tank for higher output.

√ Unique low pressure air pressure monitor.

√ Special solonoid valve to cut power and outlet all air for safety is installed.

√ To save energy and to avoid adverse effect on neighbouring cavities, relevant cavity does not blow if no preform in that cavity.

Bottle Ejection

√ Pneumatic cylinder for bottlo discharge.

√ Discharge on wind channel or belt conveyor.